INNOVATION STARTS HERE

We want to be part of the solution to move our industry forward and continue to precisely design and manufacture various atomization powder production equipment and industrial heating furnaces.

Tomorrow’s challenges demand innovation today

Changes in the energy, automotive, logistics, manufacturing and construction industries, coupled with evolving Industry 4.0 innovations, are driving the demand for new materials. Materials industry trends include solutions for sustainability, lightweight, 3D printing, and surface engineering, as well as the development of smart materials, nanoformulations, and advanced composite materials with enhanced properties. In addition, the wide application of artificial intelligence (AI), machine learning (ML), and data management practices has energized scientists to explore and develop new materials more quickly.

Our customers want to take on all these challenges. At EASYFASHION INDUSTRY, we believe innovation is the only way to get there – and we plan to lead the way.

How We Innovate

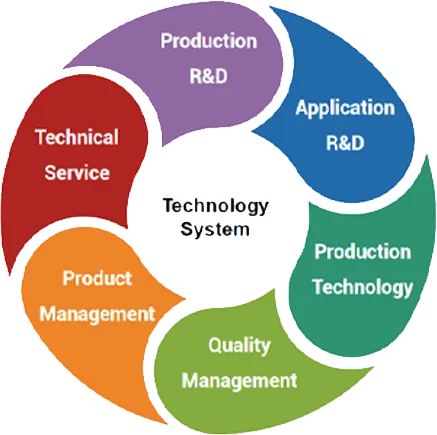

We are a team of dedicated experts and enlightened collaborators. Our innovation is driven by our customers' continuous new requirements and deepening research in the field of application. In the process of our continuous cooperation with customers, we use technological innovation and technical experiences to customize the best solutions for customers, so that they can maintain a competitive edge in the industry.

At the same time, we have skilled engineers to communicate with customers to help them solve complex problems and obtain huge production benefits.

Innovation is in our DNA

Break through the history, Create the future!

Since the establishment of EasyFashion, we have created a proud history in the high-end industries of MIM metal injection molding, carbon and silicon carbide composites, vacuum heat treatment, powder metallurgy, atomization powder, amorphous materials, photovoltaic materials and lithium battery materials. We will never stop innovating, it's in our DNA.

EasyFashion Developed And Manufactured The First Plasma Atomization Powder Production Line In China.

EasyFashion is the first company which is involved in research and developing technical solution of the third-generation semiconductor material.

EasyFashion manufactured 500kg/ batch vacuum melting inert gas atomization powder production line, which is the biggest production capacity for single unit in China. This production line is used for 3D printing industry.

EasyFashion produced the first unit of electrode induction melting gas atomization powder production line (EIGA), which is suitable for manufacturing high temperature and high purity alloy powder, such as titanium alloy powder.

Easyfashion cooperated with the Chinese Academy of Sciences to develop and manufacture the first unit of multi-functional combined atomization powder production equipment in China.

Learn more our advanced equipment gives you the opportunity to trust us

CONTACT USDo you have new interests or ideas to be realized within our field of business?

Various industries are exploring new space in the sustainable field, replying on the development of new materials and upgrading of manufacturing processes, etc., to make new materials become the "fashion" in industrial field. EasyFashion is committed to becoming a pioneer in industrial fashion, making industry a fashion and an art.

Do you or your company have an invention that could be revolutionary for the materials industry in the future, or is it just an idea or a technology, method or design that could provide a direction for future materials development? If you want to realize these creative ideas or inventions, EasyFashion may welcome them and be interested in further development. Please contact us.